We often consume powdered capsules in our daily lives, but have you ever wondered how their weight remains consistent?

In fact, this is closely related to the flowability of the powder inside the capsules. The flowability of raw materials significantly impacts product filling, weight variation in capsules and tablets, and normal production operations.

So, how can we scientifically evaluate the flowability of NMN raw materials?

1. Angle of Repose and Flowability

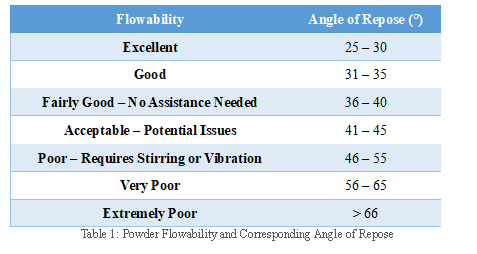

The angle of repose is the simplest method to assess powder flowability. However, different measurement techniques can yield varying results, and reproducibility is often limited. Therefore, the angle of repose should not be considered a physical constant of a powder.

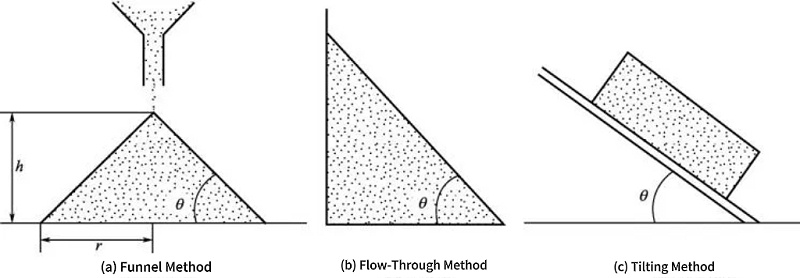

Angle of Repose (θ): This is defined as the angle formed between the surface of a freely sloping powder pile and the horizontal plane when the particles come to rest, with gravitational force and inter-particle friction in equilibrium.

Common measurement methods include the pouring method, discharge method, and tilt method, as illustrated below.

2. Compressibility, Hausner Ratio, and Flowability

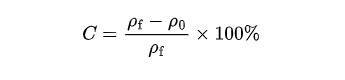

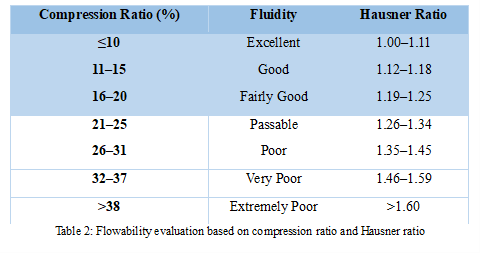

To measure compressibility, a specific amount of powder is placed in a graduated cylinder without vibration to determine its initial loose volume. After vibrating the cylinder to achieve maximum packing, the final volume is measured. Using the initial density (ρ₀) and tapped density (ρf), the compressibility index (C) can be calculated.

The Hausner ratio reflects volume changes: it is the ratio of the tapped volume (Vf) to the loose volume (Vo) of the powder.

3. Does Better Flowability Always Mean a Better NMN Product?

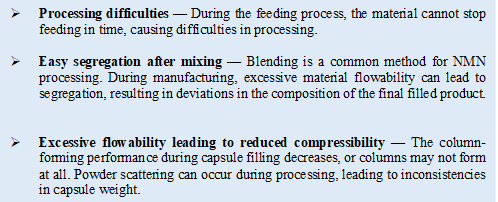

Not necessarily. Both excessively high and poor flowability can negatively impact product application and processing.

In general, the angle of repose is the most commonly used method for evaluating NMN flowability. The optimal range is recommended to be 30°–40°.

References:

[1] 潘卫三,刘伟. 药剂学. 北京: 化学工业出版社,2017.

[2] 国家药典委员会.粉体流动性测定指导原则[EB/OL].(2022.12.19)[2024.07.02].

Disclaimer: This article is intended for educational purposes and does not constitute medical or commercial advice. Information is derived from publicly available sources. Any reproduction, publication, or citation requires prior written consent from Leadsynbio.

Next:Science Publishes Clinical Trial Results: NMN Improves Muscle Insulin Sensitivity

Prev:Clinical Studies Show NMN Supplementation Can Improve Sleep Quality

Suzhou Leadsynbio Technology Co.,Ltd. is honored to be recognized inthe Hurun Future Unicorns – China Cheetahs Index 2025. This prestigious list spotlights our continued commitment to innovation and excellen...

[ Details ]Feb 09,2026